The bend deduction values in the sample bend table spreadsheets are based on formula however the true value of a bend table is the ability to provide measured results from your machinery and tooling which may not be uniform across all angles and radii. for 2D and 3D designs including AutoCAD DWG, DXF, Revit RVT and Inventor IPT. I was able, with limited success, to create sheet metal parts from models made of solids, but have been much more successful starting with surface-only models. Autodesk Inventor provides sample Imperial and metric bend tables as spreadsheet files. In Navisworks, choose Home > Append, and then choose the DWG file you want. The first step to my success in finding a reasonable workflow with sheet metal is first building a robust surface model. Revit Architecture - Tips and Tricks - Toposurface Cut Fill - Revit would indeed calculate the Cut and Fill. This was to save time, but also because the simple geometry seemed like a good fit for this tutorial.Īnother great thing about creating a paper prototype to begin with, is that I can use a caliper to pull dimensions right off the model. Ramp cut and fill April 25, 2014, 10:30 AM. To be fair, I did not create this paper model - I borrowed it from a student who chose to pursue a different concept. This works especially well for prototyping for sheet metal, because cutting, scoring and folding paper is not all that far from cutting, scoring and folding metal. We will start there.Īs I mentioned in an earlier post, I love to work out prototypes for ideas in paper before even touching cad software. But part of this work flow is starting with a concept and a well-built surface model. Inventor, however, is a different story.Īfter hours of frustrating error messages like "Self-intersecting geometry" and "Non-manifold edges", I finally found a reliable work flow for building a fully-functional sheet-metal. In solid works, it was very easy to go from a solid part to a sheet metal part - I originally designed my Glove One as a sheet metal assembly in Solidworks before deciding to 3d print it, so I am very familiar with that set of tools. And later on, they'll use the design as a template for fabricating their object in real materials. The idea of a sheet-metal-based CAD part is that you can unfold and re-fold it in the cad environment, allowing you to fully plan and design a folded part without having to constantly stop and make prototypes (though I still do that anyway!)įor one of my students' first major assignments, they are responsible for creating a fully-functional sheet metal design in AI.

#Autodesk inventor 2014 sheet metal full

when compared to Solidworks) and generally full of bugs is the Sheet Metal Features.

However, one set of tools in AI that is majorly lacking (esp. Autodesk Inventor is a great tool for the sheet metal side of our business as well as communicating our design intent. I feel pretty comfortable in this environment, mainly because it is strikingly similar to Solidworks (where I've been doing all of my CAD for the last five years).

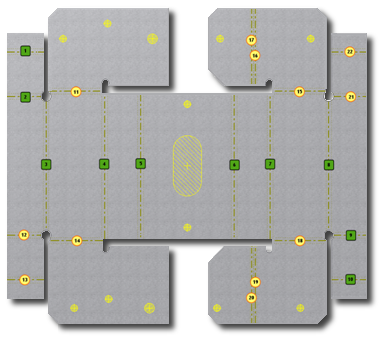

He is also PSE and ATC certified in AutoCAD, AutoCAD Mechanical, AutoCAD Electrical, Autodesk Data Management and Autodesk Inventor.As part of of CAD and Digital Fabrication course, I teach Autodesk Inventor. Mark Flayler is a senior application engineer with IMAGINiT Technologies, specializing in manufacturing environments. Sure does beat using a calculator and drawing board!įor more of Mark’s Inventor tips and tricks, check out IMAGINiT Manufacturing Solutions Blog. The next step is to use the Inventor sheet metal “Rip” command to add a gap to the duct.įinally, select the side of the duct you desire to be on the outside of the flat pattern, and pick the “Create Flat Pattern” tool. It this value is not exact, the creation of a flat pattern will fail. SolidProfessor is pleased to announce the release of our. The next step is to set the sheet metal default to match the thickness used in the Thicken/Offset command. Brand New 2015 Sheet Metal Course Released for AutoDesk Inventor. Introduction To Autodesk Inventor 2014 Surfacing.mp4 0102 Introduction - About The Author.mp4 0103 Introduction - What You Will Learn. The sheet-metal functionality in the Autodesk Inventor program is an extremely powerful toolset, centered on productivity and capturing your manufacturing. Please note that I have made the surface model invisible in the second screen shot. Mastering Autodesk Inventor - Sheet Metal Design 01. You will create a sheet metal part using the tools available in the Sheet.

#Autodesk inventor 2014 sheet metal free

In this IMAGINiT Tricks tutorial by Mark Flayler. Read Autodesk Inventor 2014 Tutorial Book by John G Ronald with a free trial. In my example, I am using 0.075″ (14 GA Mild Steel). Use Master Modeling Techniques in Autodesk Inventors Sheet Metal Environment. Next you need to use the Inventor “Thicken/Offset” command to add the desired sheet meal thickness to the inside of the branch duct surface.

0 kommentar(er)

0 kommentar(er)